# ID: 6111

## Title: The September Sweet Spot: Do This In August To Beat The October Commercial HVAC Maintenance Rush

## Type: blog_post

## Author: Ben Reed

## Publish Date: 2025-08-07T14:34:35

## Word Count: 1088

## Categories: HVAC Maintenance, Commercial Systems, Heating Systems

## Tags: carbon monoxide safety, fall heating maintenance, furnace inspection, heat exchanger inspection, HVAC business planning, HVAC maintenance, HVAC revenue optimization, maintenance agreements, preventive maintenance, seasonal HVAC planning, September scheduling, small business HVAC, technician burnout, technician training, winter emergency prevention, work-life balance

## Permalink: https://hvacknowitall.com/blog/the-september-sweet-spot-commercial-hvac-maintenance

## Description:

Key Takaways

- September maintenance prevents common winter HVAC failures including circulation pump seizures, heat exchanger cracks, and ignition problems that typically manifest in December/January

- Scheduling maintenance in September offers technical advantages (equipment accessibility, thorough inspections) and business benefits (increased profit margins, efficient routing)

- Customers avoid the October/November maintenance bottleneck when wait times stretch to 2 weeks and parts availability becomes limited

- Implementing September maintenance programs reduces technician burnout by spreading workload evenly throughout the year, reducing 60+ hour winter weeks

```

Working in residential HVAC? Read this complimentary article!

```

## The October Problem: Why Waiting Costs Everyone

Once the first cold snap hits in October, the phone starts ringing with heating emergency calls. Suddenly, everyone needs their heating systems operational *yesterday*. This creates a cascade of familiar challenges:

- Building managers discover major heat exchanger issues when they need heat most

- Parts availability plummets as suppliers can’t keep up with the surge in demand

- Emergency service rates kick in, costing clients 50-100% more than scheduled maintenance

- Technician workloads become unmanageable, creating a work-life imbalance during the heating transition

When these problems are discovered late, the consequences create legitimate safety hazards.

## The September Sweet Spot: Why It’s Ideal Timing

September offers unique advantages that make it the perfect time for commercial heating maintenance:

- Moderate weather allows system shutdowns without disrupting building occupants

- Technicians are transitioning from peak AC season to a more balanced workload

- Parts suppliers still have healthy inventory before the October/November depletion

- Building managers typically have fiscal year budget available for necessary repairs

This timing sweet spot creates a win-win situation for both service providers and clients. Technicians can work more methodically without emergency pressure, while building managers avoid the premium costs and disruption of mid-winter failures.

## The Business Case for September Maintenance in Commercial Buildings

Well-planned maintenance is essential for commercial buildings to keep critical infrastructure running smoothly and generating ROI for all stakeholders:

- Preventive maintenance delivers a 545% return on investment compared to reactive emergency repairs

- Buildings with proper heating maintenance experience 40-60% fewer winter heating failures

- Emergency repairs during peak heating season cost 50-100% more than scheduled maintenance

- Well-maintained commercial heating equipment lasts 14+ years versus just 9 years for neglected systems

As an HVAC tech, if you’re aware of the impacts to a business and can present this data effectively, you can position yourself as business partners rather than just service providers.

## Critical Commercial Systems That Can’t Wait

### Rooftop Units (RTUs)

RTUs demand specialized attention before heating season begins. This includes:

- Heat exchanger inspection using proper techniques to identify hairline cracks and corrosion

- Thorough burner inspection and cleaning to prevent carbon monoxide issues

- Control system recalibration to ensure proper heating sequences and prevent short cycling

Our detailed guide on [Gas Manifold Pressure Testing](https://www.hvacknowitall.com/blogs/blog/231593-hvac-tip----checking-manifold-gas-pressure) provides step-by-step procedures for ensuring your gas-fired RTUs operate safely and efficiently. This critical test often reveals issues that can be addressed easily in September but become emergency calls by November.

### Boiler Systems

Commercial boilers benefit tremendously from September attention:

- Comprehensive combustion analysis to optimize efficiency before the heating season demands

- Safety control verification to identify potential failure points before they become critical

- Water treatment analysis to prevent mid-winter scale buildup and efficiency losses

As covered in our [Seasonal Changeover Guide](https://hvacknowitall.com/blog/changeover-from-cooling-to-heating), proper glycol concentration verification is essential for hydronic systems to ensure freeze protection during the coming winter months. This simple step performed in September prevents catastrophic pipe failures when temperatures plummet.

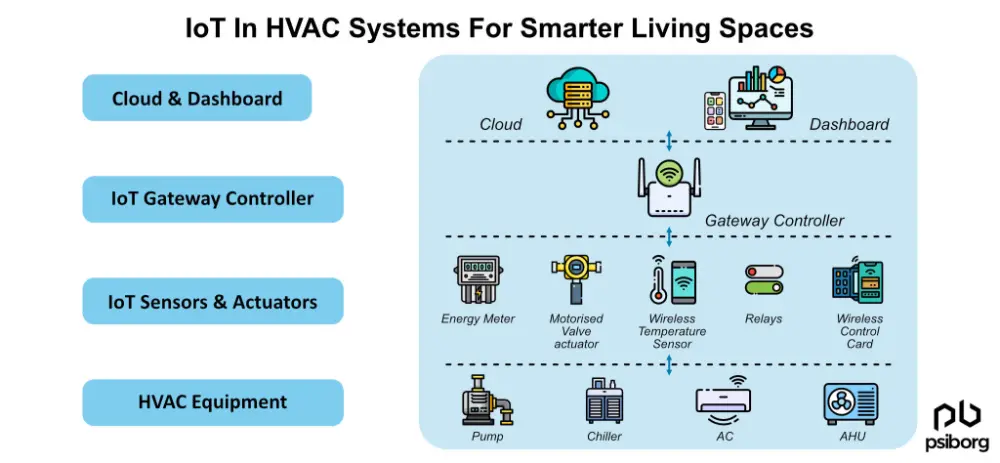

### Building Automation Systems

[The brain of your commercial building](https://hvacknowitall.com/blog/bms-basics-hvac-technician-guide) requires specialized attention:

- Schedule updates to optimize heating mode operation and prevent energy waste

- Sensor calibration verification to ensure accurate temperature readings and prevent comfort complaints

- Control sequence testing to identify programming issues before occupants require consistent heating

## Immediate Action Plan: What to Do In Early August

1. **Create a targeted outreach strategy**: Develop a list of commercial clients prioritizing those with critical operations or aging equipment.

2. **Develop a streamlined inspection checklist**: Create a September-specific checklist that focuses on heating components most likely to fail during the first cold snap.

3. **Implement a prioritization system**: Schedule the most critical systems first—hospitals, elder care facilities, schools, and buildings with previous heating issues.

4. **Set up a parts inventory plan**: Coordinate with suppliers to ensure availability of commonly needed heating components.

When discussing flame rectification systems, reference our guide on [Why Flame Rod Failures Happen and How To Prevent Them](https://hvacknowitall.com/blog/why-flame-rod-failures-happen-and-how-to-prevent-them), which provides technical insights that can help you identify potential issues before they cause no-heat conditions.

## Long-Term Strategy: Building a September Maintenance Program

To truly differentiate your commercial service, develop a systematic September maintenance program:

- Create an annual reminder system to book commercial clients specifically for September heating checks

- Develop educational materials explaining the September advantage for building managers

- Implement technician training focused on efficient heating system inspections

- Build performance tracking that documents reduced winter emergency calls after September maintenance

For comprehensive maintenance of specialized systems, our guide on [Make Up Air Units](https://hvacknowitall.com/blog/make-up-air-units-explained) provides detailed procedures for both direct-fired and indirect-fired systems, which are often overlooked during standard maintenance but critical to proper building operation.

## Communication Strategies for Building Managers

The success of September maintenance often relies on effective communication with building managers:

- Frame conversations around budget protection rather than maintenance costs

- Address the “it’s still hot outside” objection with data on equipment lead times

- Present tenant satisfaction benefits of avoiding mid-winter heating emergencies

- Provide documentation that helps justify maintenance expenditures to upper management

These conversations build trust and position you as a proactive partner rather than a reactive vendor.

## The September Advantage

Implementing September heating maintenance sets commercial HVAC technicians apart as true professionals in an industry often driven by reactive service. This approach delivers multiple benefits:

- Peace of mind from addressing issues before they become emergencies

- Balanced workload that prevents the October/November service chaos

- Higher client satisfaction and stronger long-term relationships

- Increased revenue through more efficient service delivery

By embracing the September advantage, you position yourself as a strategic asset to your clients rather than just another service provider.

```

Important Note: As our guide on Carbon Monoxide Testing emphasizes, safety must remain the top priority in all heating maintenance. September inspections provide the time needed to thoroughly evaluate combustion safety without the pressure of freezing occupants or emergency conditions.

```

--------------------------------------------------

# ID: 6104

## Title: The September Sweet Spot: Why Smart Residential Techs Schedule HVAC Maintenance In August

## Type: blog_post

## Author: Ben Reed

## Publish Date: 2025-08-07T13:28:12

## Word Count: 1541

## Categories: HVAC Maintenance, Heating Systems

## Tags: carbon monoxide safety, fall heating maintenance, furnace inspection, heat exchanger inspection, HVAC business planning, HVAC maintenance, HVAC revenue optimization, maintenance agreements, preventive maintenance, seasonal HVAC planning, September scheduling, small business HVAC, technician burnout, technician training, winter emergency prevention, work-life balance

## Permalink: https://hvacknowitall.com/blog/the-september-sweet-residential-spot-hvac-maintenance

## Description:

Key Takeaways

- September maintenance prevents common winter HVAC failures including circulation pump seizures, heat exchanger cracks, and ignition problems that typically manifest in December/January

- Scheduling maintenance in September offers technical advantages (equipment accessibility, thorough inspections) and business benefits (increased profit margins, efficient routing)

- Customers avoid the October/November maintenance bottleneck when wait times stretch to 2 weeks and parts availability becomes limited

- Implementing September maintenance programs reduces technician burnout by spreading workload evenly throughout the year, reducing 60+ hour winter weeks

```

Working in commercial HVAC? Read this complimentary article!

```

## Why Timing Matters for Shoulder Season Maintenance

Are you ready for the October maintenance rush. Probably not.

Data shows October and November rank as the busiest maintenance months for HVAC contractors, creating a bottleneck that leaves customers waiting up to two weeks for service.

By the time most customers think about heating maintenance, it’s already too late. They call when the first cold snap hits, and suddenly everyone wants their furnace checked at once. This creates a scheduling nightmare that forces you to rush through jobs, miss important safety checks, and work overtime that could have been avoided.

[Changing over from cooling to heating](https://hvacknowitall.com/blog/changeover-from-cooling-to-heating) is a process that requires careful inspection and preparation. When systems sit dormant for months, problems develop that only manifest when they’re first fired up – usually on the coldest day of the year.

## What’s Breaking Down This Winter (And Why)

After sitting dormant all summer, heating systems develop predictable failure points that smart technicians check before problems occur. Here are the top components to inspect during September maintenance:

1. **Circulation Pumps**: These top the failure list after summer inactivity. Pump seizure due to 3-4 months of dormancy is a primary breakdown cause. A simple manual rotation during September can prevent an expensive mid-winter replacement.

2. **Induced Draft Motors**: These critical components often seize after months of inactivity due to moisture infiltration and bearing lubricant thickening. The bearings in these motors are particularly vulnerable to corrosion when the system isn’t running regularly. A preventative check includes testing for smooth operation, proper amperage draw, and inspecting wheel clearance before winter demand pushes these motors to failure.

3. **Ignition Systems**: Ignitors frequently fail due to exhaust gas recirculation during startup. Testing spark location and conductivity now prevents no-heat calls later.

4. **Burners**: Summer humidity causes rust and corrosion on burner surfaces, leading to improper flame patterns and inefficient combustion when winter arrives. Carefully inspect burners for warping, rust, and proper alignment, then clean thoroughly with appropriate brushes and compressed air. Many techs skip this step, but it’s essential for preventing carbon monoxide issues and ignition failures.

5. **Flame Sensors**: These develop contamination buildup during the off-season that leads to system failures. A quick cleaning in September ensures reliable ignition when temperatures drop.

6. **Heat Exchangers**: Heat exchanger inspection deserves special attention during September maintenance. Even small cracks can release deadly carbon monoxide into living spaces when systems activate for winter. CO is known as the [silent killer](https://hvacknowitall.com/blog/carbon-monoxide-the-silent-killer-every-tech-should-know-how-to-handle) because it’s odorless, colorless, and dangerous at just 70 ppm, with 400 ppm potentially causing death within hours. Professional-grade testing equipment allows technicians to check ambient air, mechanical rooms, and flue gas during maintenance visits – any reading above 200 ppm in flue gas or detection in the air stream indicates an immediate safety hazard requiring system shutdown.

7. **Condensate Drains**: One of winter’s most overlooked failure points is condensate drainage systems in high-efficiency furnaces. After months without operation, organic growth, debris accumulation, and trap evaporation create perfect conditions for water backups that trigger pressure switches and shut systems down. Many emergency “no heat” calls are simply condensate issues that could have been prevented with September maintenance. Thoroughly flush these lines, verify proper trap depth, and consider adding condensate treatment tablets as preventative maintenance

8. **Control Boards**: The “brain” of modern furnaces often fails after power surges during summer thunderstorms. Testing all functions during the mild weather allows for planned replacement rather than emergency service. [Learn more about control board components here.](https://hvacknowitall.com/blog/guide-to-hvac-pcb-components)

January experiences the highest breakdown rate at 15% of annual heating system failures, followed by December at 12%. [By addressing these components during September’s maintenance sweet spot](https://hvacknowitall.com/blog/the-truth-about-furnace-tune-ups), you’re preventing the most common emergency calls while protecting your customers’ comfort and safety.

## Immediate Actions in August

The time to act is now, not when the rush hits. Here are the concrete steps you can take in early august to leverage the September sweet spot:

### Customer Communication Templates

Start with your existing customer base. Send a simple email with this message:

> *“Beat the October rush! Schedule your heating system maintenance in September and receive priority scheduling, our thorough 21-point safety inspection, and peace of mind before the cold weather hits. Plus, mention this email for $25 off when you book this week.”*

For text messages, keep it even simpler:

> *“HVAC Alert: Book your heating maintenance in September to avoid the October rush and potential parts delays. Reply YES for priority scheduling.”*

These templates have produced open rates of 20% for email and 98% for text messages, significantly outperforming industry averages.

### How to Pitch September Maintenance During AC Calls

Every summer service call is an opportunity to book fall maintenance. Here’s a script that works:

> *“While I’ve got your AC running great today, I noticed your heating system hasn’t been checked since last year. Most of our customers book their heating maintenance in September to avoid the October rush when everyone calls at once. Would you prefer a morning or afternoon appointment in the second week of September?”*

This approach uses the psychology of choice rather than yes/no questions, increasing booking rates by up to 35%. By presenting it as something “most customers do,” you’re establishing a social norm that makes the decision easier.

## The Business Case for September

As a solo technician or small shop owner, September maintenance offers a direct path to more stable income and better work-life balance. While emergency calls might seem more profitable at $950 versus $250 for maintenance, consider the hidden value: maintenance calls take half the time, create repeat customers, and can be scheduled on your terms. This means you can complete 6-8 maintenance visits daily compared to 3-4 emergency calls, with less stress and more predictable hours.

For small operations, simple maintenance agreements don’t need fancy software or complicated contracts. Start with a basic one-page agreement offering two seasonal checks (fall and spring), priority emergency service, and a 10% discount on repairs. Price it reasonably at $199-299 annually, and begin by offering it to your most satisfied customers. Even securing just 25 maintenance agreements creates a reliable $5,000-7,500 revenue base that helps smooth seasonal income fluctuations.

The beauty of September maintenance for small shops is that it transforms your business model from “waiting for the phone to ring” to proactively scheduling your workload. While we recommend you use a proper fleet management solution (like Housecall Pro), you can use a simple spreadsheet to track customer equipment age and maintenance history, then group appointments by neighborhood to maximize efficiency.

Many successful one-person operations report that maintenance agreements eventually represent 30-40% of their total revenue while requiring only 20% of their labor hours – making them the most profitable aspect of their business.

## Building Long-Term Strategy

September’s calmer pace creates the perfect opportunity for training newer technicians before emergency season hits. Pairing experienced professionals with apprentices during maintenance calls allows for hands-on learning without the pressure of emergency situations. Companies report technicians trained through structured September maintenance programs experience 40% lower error rates during their first heating emergency season, building the reliability and discretionary effort that distinguish successful HVAC professionals.

Perhaps most importantly, strategic September scheduling dramatically improves technician quality of life by spreading workload more evenly throughout the year. This approach helps professionals avoid the 60+ hour weeks that contribute to our industry’s troubling 18-22% first-year turnover rate. Companies implementing structured September maintenance programs report a 35% reduction in technician overtime hours during winter months and corresponding 27% decrease in turnover. This creates space for both excellent customer service and technician [work-life balance](https://anchor.fm/hvacknowitall/episodes/Work-Life-Balance-And-Why-Its-Important-e1tjt0e), essential for long-term career satisfaction.

## Your September Action Plan

Here’s your action plan to make it happen:

1. **Early August**: Set up a simple email and text campaign to existing customers promoting September maintenance.

2. **During Every AC Call**: Pitch September heating maintenance using the choice-based script.

3. **Create Your Packages**: Develop tiered maintenance offerings that provide clear value while maintaining healthy margins.

4. **Train Your Team**: Ensure all technicians understand the technical and business benefits of September maintenance so they can confidently communicate them to customers.

5. **Document Everything**: Use digital documentation tools to thoroughly record all findings during September maintenance, creating a baseline for future service.

The difference between a good technician and a great one often comes down to [five minutes of extra attention](https://hvacknowitall.com/blog/five-minutes-to-be-a-better-tech). September maintenance gives you the time to be thorough, catch problems before they become emergencies, and build relationships that last beyond a single service call.

Your customers get reliable heating when they need it most. You get a more predictable schedule and income stream. Everyone wins in the September sweet spot.

--------------------------------------------------

# ID: 6068

## Title: Bi-Flow TXVs in Heat Pumps: How They Work & Why They Matter

## Type: blog_post

## Author: Julian Finbow

## Publish Date: 2025-07-23T16:56:02

## Word Count: 1032

## Categories: Components, Heat Pumps

## Tags: bi-flow TXV, condenser, cooling mode, Danfoss TGE, discharge gas, evaporator, external equalization, heat pump, heat pump troubleshooting, heating mode, HVAC components, metering device, refrigerant flow, refrigeration cycle, reversing valve, suction line, system design, thermostatic expansion valve, TXV, valve sizing

## Permalink: https://hvacknowitall.com/blog/bi-flow-txvs-in-heat-pumps-how-they-work-why-they-matter

## Description:

## Understanding Heat Pump Refrigerant Flow Challenges

The **Thermostatic Expansion Valve** (TXV) remains one of the most reliable metering devices in HVAC systems, but heat pump applications present unique challenges. Unlike standard air conditioning systems, heat pumps must accommodate refrigerant flow in both directions during heating and cooling cycles.

*A 3D cross section of a Danfoss TR6 Bi-Flow TXV*

This is where specialized “**Bi-Flow” TXVs** become crucial to system performance. While some systems use standard TXVs with separate check valve bypasses or even dual TXV configurations, bi-flow TXVs offer an elegant solution by handling refrigerant flow in both directions with a single component.

In this article, we’ll explore how these specialized valves work, focusing on the Danfoss TR6 Bi-Flow TXV, and why understanding their operation is essential for any HVAC professional working with heat pump systems.

**Note**: Understanding [TXV operation](https://hvacknowitall.com/blog/adaptive-vs-fixed-expansion-valves) and [Heat Pump Reversing Valves](https://hvacknowitall.com/blog/reversing-valves-and-their-control-designation) is important to obtain the key takeaways from this article.

## How Bi-Flow TXVs Solve the Reversing Problem

*Simplified air conditioning / heat pump system (bi-flow)*

Referencing the above image, we will focus on the function of the [**Danfoss TR6 Bi-Flow TXV**](https://www.danfoss.com/en/products/dcs/valves/thermostatic-expansion-valves/thermostatic-expansion-valves/tr-6-thermostatic-expansion-valves/#tab-overview). This drawing from the valve’s [**Data Sheet**](https://assets.danfoss.com/documents/407758/AI246186497192en-001002.pdf) highlights the operation of the system in Cooling Mode.

```

Note: As mentioned, there are different ways to achieve heat pump operation with TXVs (this is also outlined in the TR6 Data Sheet). Our example will focus on the use of a single Bi-Flow TXV with no check valves.

```

## Cooling Mode Operation Explained

Cooling mode operation is similar to any other **Air Conditioning** or **Refrigeration** System. Through the Reversing Valve, the **Compressor’s Discharge Gas** is allowed to flow into the **Outdoor Coil** to reject heat and **Condense**. Liquid is then fed through the Bi-Flow TXV in its *Conventional Flow Direction* (more on this later). The liquid refrigerant absorbs heat and **Evaporates** in the Indoor Coil before returning to the Compressor.

**Note:** The TXV has its **Sensing Bulb** and **External Equalization Tube** installed in the Compressor **Suction Line**, instead of on the “Evaporator Outlet” like it would be in a plain AC System. This will allow proper TXV Control during the **Heating Cycle** as well. When mounting the sensing bulb, position it at the 10 or 2 o’clock position for suction lines 7/8″ or smaller, and at the 4 or 8 o’clock position for suction lines larger than 7/8″. This specific positioning is critical because refrigerant tends to stratify differently depending on line size.

## Heating Mode Operation Explained

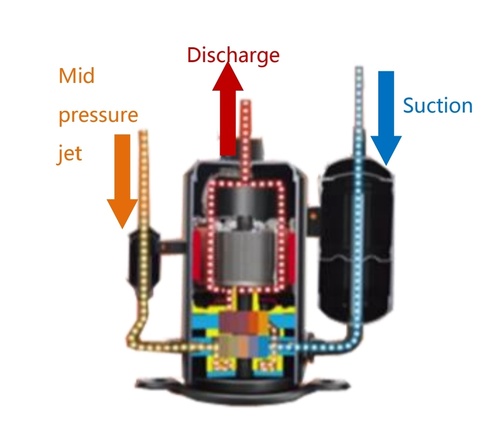

In Heating Mode, the piston in the Reversing Valve moves to allow system flow to reverse. This directs hot Discharge Gas to the Indoor Coil for heating, and the Condensed refrigerant now feeds the Bi-Flow TXV in the *Reverse Flow Direction*. The refrigerant is then able to feed the Outdoor Coil, and absorb heat from the outdoors while Evaporating.

*TR6 Static/opening superheat graph*

**Note:** The above image from the [TR6 Data Sheet](https://assets.danfoss.com/documents/407758/AI246186497192en-001002.pdf) shows a setback of a Bi-Flow TXV. The setback of this set-up for a Heat Pump is that the TR6 has a slight capacity reduction (how much heat transfer it can support) in the Reverse Flow Direction. In this example, we are “Bias towards Cooling”, as we have more capacity in the Cooling Mode. This is made up for in this design by fewer total components and gained system simplicity.

## The Danfoss TR6 Bi-Flow TXV Design

In the Danfoss TR6 Manual (below), the design of the valve internals and pin is explained to give this TXV the characteristic to support refrigerant flow in both directions.

[AI318728845972en-000407](https://hvacknowitall.com/wp-content/uploads/2025/07/AI318728845972en-000407.pdf)[Download](https://hvacknowitall.com/wp-content/uploads/2025/07/AI318728845972en-000407.pdf)

With the valve’s External Equalization Port (and Sensing Bulb) installed in the Compressor Suction Line (instead of one of the coil’s outlets), this allows the valve to reference “Evaporator” Outlet Pressure accurately, regardless of which mode it operates in or the current outdoor/indoor conditions.

## Performance Considerations: Capacity in Reverse Flow

One important consideration when working with bi-flow TXVs is their performance in reverse flow mode. As shown in the Danfoss TR6 documentation, there’s typically a slight capacity reduction when the valve operates in the reverse flow direction. System designers account for this when selecting components, often biasing the system toward cooling performance where maximum capacity is most critical.

This trade-off is generally acceptable because the simplified system design (fewer components, less potential leak points) outweighs the small capacity reduction. Additionally, modern heat pump systems often include supplementary heating for extreme cold conditions when maximum heating capacity would be needed.

## Common Troubleshooting Issues

When working with heat pump systems using bi-flow TXVs, be aware of these common issues:

1. **Improper sensing bulb mounting**: The sensing bulb must be securely attached to the suction line with good thermal contact

2. **External equalization line restrictions**: Any kinks or blockages will cause improper valve operation

3. **Valve sizing issues**: An undersized valve can restrict flow and reduce system capacity

4. **Refrigerant charge problems**: Proper charge is critical for optimal valve operation in both directions

***Related: In a recent podcast, Jamie breaks down how these valves work in both heating and cooling modes and why they need to handle refrigerant flow in two directions. They discuss the parts of a TX valve, how pressure and temperature control the flow, and why Danfoss uses stainless steel in their design.***

## Key Takeaways

When working with heat pump systems using bi-flow TXVs, remember these key points:

- Bi-flow TXVs allow refrigerant to flow in both directions without additional check valves

- External equalization and sensing bulb placement are critical for proper operation

- Some capacity reduction in reverse flow is normal and accounted for in system design

- TXV selection should match the specific heat pump application requirements

- The simplified system design typically outweighs the minor capacity reduction in reverse flow

As the industry continues to evolve toward more electronic expansion valves (EEVs) and inverter-driven compressors, the principles of bi-directional flow control remain important. For technicians working on conventional heat pump systems, understanding bi-flow TXV operation is a valuable skill that leads to better diagnostics and more efficient system performance.

--------------------------------------------------

# ID: 5994

## Title: HVAC Design Heat Load Factors: Finding the Shortcuts

## Type: blog_post

## Author: Drew Towzer

## Publish Date: 2025-07-10T14:54:12

## Word Count: 1516

## Categories: Heat Pumps, HVAC Installation

## Tags: accurate equipment sizing, AFUE rating, energy consumption data, gas consumption sizing, heat load factor, heat pump sizing guide, home heating requirements, HVAC contractor tools, HVAC rule of thumb, HVAC sizing shortcut, oversized equipment, performance-based heat load, quick heat load calculation, right-sized heat pumps, virtual quotes

## Permalink: https://hvacknowitall.com/blog/hvac-design-heat-load-factors-shortcut

## Description:

[](https://www.amazon.ca/dp/1781339163/)

*This article is **Part 3** of a 3-part series on heat load calculations and proper HVAC sizing by Drew Tozer for HVAC Know It All. Read [**Part 1**](https://hvacknowitall.com/blog/heat-load-factors-a-simplified-method-for-10-second-load-calculations) & **[Part 2](https://hvacknowitall.com/blog/heat-loads-in-the-real-world-precision-versus-accuracy).*** Drew’s book “**[Feel-Good Homes](https://www.amazon.ca/dp/1781339163/)**: How to choose the right heat pump for a comfortable, healthy, sustainable home” is available for purchase now. *NOTE: This information is tailored towards cold climates / heating-dominated regions.*

## A Common Factor, Then a Theory

When I was completing energy assessments for homeowners, I noticed that the modelled energy consumption was frequently *20x* the gas consumption.

I assumed it was a coincidence, and I didn’t dig into the data.

I also didn’t have a way to check the numbers on a bigger scale. But heat load calculators that were based on the same methodology started to be released, which gave me the opportunity to test my theory (~20x the gas consumption).

I used [thermalpoint.ca](http://thermalpoint.ca/) (developed as a collaboration in Toronto between TRCA, STEP, and TAF). It’s a calculator for Ontario homeowners–it follows the same process but it does the HDD lookup in the backend.

See the image below. I recorded heat loads (output) for different scenarios:

- 200 m³ increments from 1,000 – 3,000 m³

- Compared 90% and 95% AFUE (efficiency rating)

- Compared Toronto, Ottawa, and Thunder Bay (not shown)

Look at the results!

*Figure 2. Summary table of inputs and outputs for various scenarios in the [thermalpoint.ca](http://thermalpoint.ca/) heat load calculator.*

The “load factor” is 19 across every scenario. I adjusted the results to exclude AFUE, so the heat load calculation would be: gas usage \* 19 \* AFUE.

Assuming AFUE of the existing equipment is *around* 92%, we get the magic 17.5 **heat load factor** for Toronto.

I ran the test in reverse, using the **heat load factor** to calculate heating loads, and comparing it to the output from the calculator. The results were +/- 1,000 BTU/hr.

The results were similar in Toronto, Ottawa, and Thunder Bay. That surprised me, given the difference in design temperatures (4°F, -7°F, and -16°F, respectively).

My best guess is that the two temperature metrics roughly cancel out. The calculation includes “heating degree days” in the numerator and “indoor set point minus design temperature” in the denominator. I expect they’re strongly correlated within a climate zone.

## Next Steps: Calculate Your Heat Load Factor

Let’s talk about a shortcut for the quoting process. Do the *full calculation* for the next 10 projects. Choose projects with common AFUE ratings like 90-96%.

Once you have all 10, write them in an Excel sheet with three columns: gas usage, heat load, and heat load factor. You already have gas usage and heating load. To get the **heat load factor**, divide heating load by gas usage (therms or m³).

How does it look?

Are the numbers in the third column consistent? You can check for outliers, but otherwise take the average.

That’s your local **Heat Load Factor (HLF).**

Now you have a shortcut for accurate heat loads.

## **A method to do accurate heat load calculations in 10 seconds or less.**

Ask the homeowner for their annual gas usage, adjust for gas water heating (minus 300 m³ or 100 therms), and multiply by your calculated **HLF**.

I added “annual gas usage” and “water heat fuel type” to my company’s *Homeowner Intake Form*, so I get the information upfront. Now I confidently give virtual quotes for right-sized heat pumps.

*Foundry Heat Pumps Homeowner Intake Form*

And if you don’t have a dynamic *Homeowner Intake Form*, get one!

## Real-World Application

Let’s look at an example. A Toronto homeowner who wants a heat pump to replace their furnace and AC. From their *Homeowner Intake Form* we know:

1. Annual gas usage: 1,300 m³ (460 therms)

2. Does the furnace have plastic exhaust pipes or metal? Plastic (i.e. it’s likely 90-97% efficient)

3. Water heating fuel? Electric

Take a second. What equipment do we quote?

The **heat load factor** in Toronto is 17.5x (50x), it’s a high-efficiency furnace, and there’s no adjustment needed for water heating (it’s electric, not gas).

**Answer:** I’d confidently quote a 2-ton heat pump to cover the ~23,000 BTU/hr heat load (1,300 x 17.5 or 460 x 50 = 23,000).

Yes, I copied the gas usage from the story in the introduction. The one where the contractor quoted a 7-ton gas furnace. We got a slightly different answer (23 KBTU versus 26 KBTU), but it’d lead to the same equipment. Again, the goal is *close enough*.

Even if you don’t use **heat load factors** as your *only* sizing criteria (note: you shouldn’t), it’s extremely useful as a sizing rule-of-thumb for HVAC in cold climates. You’ll immediately know that a Toronto house with 1,300 m³ (460 therms) of gas heating needs a 2-ton heat pump, *not* a 7-ton furnace.

## Why This Matters for System Performance

Traditional rules-of-thumb for sizing (like 1 ton per 400 sqft) are useless because they’re based on data that doesn’t directly impact heat loads. A modern, well-built 3,000 sqft house that’s airtight and well-insulated may need less heat than an old 1,000 sqft bungalow that’s leaky and uninsulated.

A rule-of-thumb based on square footage won’t reflect that—but gas usage will reflect how the house performs under real-world conditions.

This illustrates perfectly why right-sized equipment matters, especially when transitioning to heat pumps. The solution, as Gary suggests, is to “size closer to the cooling load but as close to the heating load as possible” and supplement with auxiliary heat when needed.

## Limitations and Adjustments

*IECC North America Climate Zones*

First, this works best for heating-dominated climates. Warm climates have an extra variable that complicates everything: **humidity**.

Second, pay attention to indoor setpoints. Homeowners that keep the thermostat at 65°F all winter will throw off the calculation. You can adjust the HDD baseline to account for extreme setpoints.

And third, gas consumption directly correlates to winter temperatures, so we need to adjust the **heat load factor** annually based on the *coldness* of each winter. The amount of cold that the house had to fight against to stay warm all winter. We can use heating degree days to assess “coldness”.

The **heat load factor** for Toronto is 17.5x (50x) for 2024 gas consumption. If 2025 is 10% colder (i.e. 10% more heating degree days), adjust the **heat load factor** down by 10%.

Notice that it’s an inverse relationship because *more* HDD means *colder*. A 10% *increase* in HDD results in a 10% *decrease* in the HLF—a colder winter naturally forces every house to use more energy for heating, so the same gas usage in a colder winter means a higher performing house (i.e. lower heat load).

## Avoiding Common Heat Pump Sizing Mistakes

This approach helps avoid one of the most common mistakes in HVAC: oversizing equipment. As explained in the HVAC Know It All article on [heat pump oversizing](https://hvacknowitall.com/blog/heat-pump-oversizing-what-every-hvac-tech-needs-to-know), “Many oversizing issues stem from incorrectly performed load calculations. A concerning practice involves deliberately ‘manipulating’ Manual J calculations to justify larger equipment.”

Using real-world energy consumption data provides a reality check against these inflated calculations. The Heat Load Factor method gives you a realistic starting point that can be validated with other assessment methods during your site visit.

For a deeper dive into proper heat pump sizing and installation considerations, check out the podcast below where Gary and I discuss how systems should be sized with care, not guesswork, so homes stay comfy, air stays clean, and systems last longer without costly breakdowns.

## Final Thoughts

Now that you know all the shortcuts to load calculations, put it into practice in your HVAC business:

- **Integrate With Existing Processes** – Ask about gas consumption in your intake forms to gather the data needed for Heat Load Factor calculations upfront.

- **Provide Confident Virtual Quotes** – Leverage performance-based calculations to deliver accurate equipment sizing recommendations remotely, but a disclaimer on virtual quotes that final pricing requires a site visit to confirm measurements and logistics.

- **Pre-Qualify Customers** – Use the Heat Load Factor method and virtual quotes to quickly identify and avoid price-shopping customers seeking the lowest bid regardless of proper sizing.

- **Streamline Premium Service** – Position yourself as a premium contractor by offering accurate heat pump sizing quotes without time-consuming initial site visits.

- **Assess Infrastructure Limitations** – During the site visit, measure existing ductwork and static pressure during your final site assessment to validate your heat load factor calculations. And confirm that the electrical panel can support the recommended setup.

By consistently using this approach, you’ll avoid the comfort issues associated with oversized equipment while ensuring your heat pump installations perform as designed. Your customers will appreciate the improved comfort, and you’ll build a reputation for installing systems that actually work as intended.

---

*This article is **Part 3** of a 3-part series on heat load calculations and proper HVAC sizing by Drew Tozer for HVAC Know It All. Read [**Part 1**](https://hvacknowitall.com/blog/heat-load-factors-a-simplified-method-for-10-second-load-calculations) & **[Part 2](https://hvacknowitall.com/blog/heat-loads-in-the-real-world-precision-versus-accuracy).***

--------------------------------------------------

# ID: 5984

## Title: HVAC Design Heat Loads in the Real World: Precision Versus Accuracy

## Type: blog_post

## Author: Drew Towzer

## Publish Date: 2025-07-10T02:27:22

## Word Count: 1213

## Categories: Heat Pumps, HVAC Installation

## Tags: accurate heat loads, AFUE, BTU calculation, degree days, design temperature, energy consumption data, energy modeling, gas usage analysis, heat load calculation, heat pump sizing, heating degree days, HVAC sizing, oversized equipment, performance-based sizing, runtime data

## Permalink: https://hvacknowitall.com/blog/hvac-design-heat-loads-precision-versus-accuracy

## Description:

[](https://www.amazon.ca/dp/1781339163/)

*This article is Part 2 of a 3-part series on heat load calculations and proper HVAC sizing by Drew Tozer for HVAC Know It All. Read **[Part 1](https://hvacknowitall.com/blog/hvac-design-heat-load-factors-shortcut)** & [**Part 3**](https://hvacknowitall.com/blog/hvac-design-heat-load-factors-shortcut). Drew’s book “**[Feel-Good Homes](https://www.amazon.ca/dp/1781339163/)**: How to choose the right heat pump for a comfortable, healthy, sustainable home” is available for purchase now.* *NOTE: This information is tailored towards cold climates / heating-dominated regions.*

## Modelled Versus Performance-Based Heat Load Calculations

There are three types of heat load calculations:

1. Traditional rules of thumb (“1 ton per 400 sq ft”)

2. Energy models (theoretical)

3. Performance-based (real-world data)

Within performance-based heat load calculations, you can use energy consumption or runtime data. Energy consumption (also called energy usage or gas usage) looks at how much gas (or another fuel) is used to heat the house. Unlike rules of thumb and energy models, energy consumption is based on how the house performs under real-world conditions.

*Thermostat Runtime Example. Image Credit: AS Air Home*

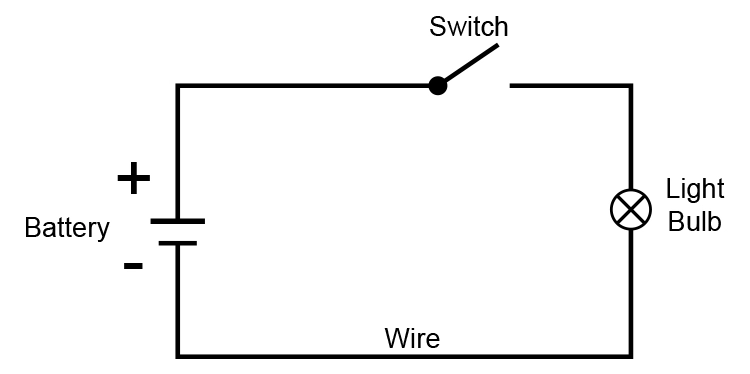

Runtime data is simply looking at *how long* the equipment operates at specific outdoor temperatures. If a 60,000 BTU/hr furnace runs for 30 minutes in an hour that matches outdoor design conditions, then the heating load is 30,000 BTU/hr (30 minutes / 60 minutes \* 60,000 BTU/hr = 30,000 BTU/hr).

*Monthly Gas Bill Example.*

My preference is energy consumption because **it’s easier to get a monthly gas bill than thermostat data**. Runtime data can also be difficult to interpret for multiple-stage or variable furnaces.

## Why Traditional Methods Fall Short

Traditional rules of thumb are crude guesses. They’re quick but unreliable and unlikely to provide the right answer.

Energy models aren’t much better—whether it gets you *close enough* depends on the accuracy of the model, the underlying assumptions, and the complete and accurate collection of household data like insulation levels, orientation, shading, air leakage, etc.

Models are **conservative** (they overestimate) and we often input conservative values to *play it safe*. That’s margin on margin.

The biggest issue with a modelled heat load is that **it might be right—or wildly wrong. There’s no way to tell.**

To prove my point, here’s a thought experiment: a homeowner gets an energy assessment completed. They give the report to you (the contractor) and it includes a 32,000 BTU/hr heating load. Is it an overestimate, underestimate, or *close enough*?

*Energy Assessment Report. Image Credit: City of Nanaimo*

***How would you know?***

You could double check the report and confirm basic metrics like square footage, number of floors, location, and window count. But you won’t know the exact measurements, air leakage, insulation levels, etc. And since air leakage is the biggest source of heat loss, **you *can’t* know if it’s accurate or not.**

But if that same homeowner (located in Toronto, for my convenience) tells me they used 1,500 m³ (530 therms), I know their heating load is *about* 26,000 BTU/hr. Then I can recommend a [2-ton or 2.5-ton heat pump](https://hvacknowitall.com/blog/heat-pump-oversizing-what-every-hvac-tech-needs-to-know) based on other factors.

Most HVAC systems are oversized because the heat loads were overestimated (with margins on margins) and the equipment has been replaced like-for-like for the life of the house. An *old* oversized furnace gets replaced with a *new* oversized furnace.

## Gas Usage for Heat Loads: The Long Way

The idea is simple: a house with a furnace burns gas for heat. The more heat the house needs, the more gas it burns. So, we can look at the amount of gas *used* to assess how much heating the house *needs*.

For this heat load method, we need four things:

1. Gas consumption

2. Equipment efficiency

3. Outdoor temperatures

4. The 99% design temperature.

For outdoor temperatures, we’ll use a metric called **heating degree days**. It’s a combination of time and temperature that reflects how much heating or cooling was needed to keep an indoor temperature constant.

*Image Credit: Weatherbit*

Outdoor temperatures are compared to a baseline temperature (usually 60°F or 65°F). If the mean temperature is 64°F for a day…well, that’s 1 degree day. While heating degree days can be counted in Celsius, we’ll need to use Fahrenheit because BTU and BTU/hr are based in Fahrenheit.

For context, Toronto has ~7,000 heating degree days with a 65°F baseline. A colder city like Edmonton has 10,000+. In US terms, think Portland, Maine (7,000 HDD) versus Anchorage, Alaska (10,000+).

Here are the steps for the heat load calculation:

1. Calculate annual BTUs of heating (from m³/therms and equipment AFUE)

2. Lookup heating degree days (HDD) for the time period

3. Divide BTU by HDD (BTU per degree-day)

4. Divide by 24 (BTU per degree-hour)

5. Multiply by design/thermostat differential

6. **That’s your heating load!**

We take the full amount of heating used (convert gas usage to millions of BTUs), taking into account equipment efficiency. Then we look up the heating degree days for our area and time period ([degreedays.net](http://degreedays.net/) is easy).

Now we divide BTU by HDD to understand how much heat (BTU) we need per degree-day. Divide again by 24 to get BTU per degree-hour.

We’re aiming for a heating load (BTU/hr), so intuitively it feels close that we have a BTU per degree-hour number. We just need to eliminate the “degree” unit—and we do that with the design temperature. Or rather, the difference between the indoor setpoint (70°F) and the design temp.

For Toronto, the 99% design temperature (found on [ASHRAE](https://ashrae-meteo.info/v2.0/index.php)) is 4°F, so the *difference* between indoor and outdoor temperatures will be 66°F (70 minus 4 equals 66).

If our Toronto house needed 360 BTU per degree-hour, then the heating load is ~24,000 BTU/hr (360 \* 66 = 23,760).

That’s the *long* way of doing it (although significantly faster than energy modelling). Tools like [thermalpoint.ca](http://thermalpoint.ca/), [knowyourload.ca](http://knowyourload.ca/), and [thermentor.com](http://thermentor.com/) are making it easier and faster.

## How This Affects Your Heat Pump Sizing

Getting the heat load right is critical for properly sizing heat pumps. As Gary notes in his [heat pump installation guide](https://hvacknowitall.com/blog/central-heat-pump-install-considerations), ductwork constraints often limit how large your heat pump can be. If you size strictly to an overestimated heat load, you may encounter airflow problems.

> “If a home has a heat loss of 60k BTU and a heat gain of 24k BTU, how do we size? A heat pump will need 400-450 CFM per ton to run effectively. If we size to the heating load, we need 2000-2250 CFM. In most retrofit applications, we’ll find ductwork only designed to carry 800-1200 CFM.”

The solution is to size closer to the cooling load but as close to the heating load as possible, then supplement with auxiliary heat as needed. This is exactly why accurate heat load calculations are so important.

## Simplifying the Process

For contractors and homeowners who want to skip the manual calculations, several online tools make this process much simpler. But the principle remains the same: **using actual energy consumption data will generally give you a more accurate heat load estimate than theoretical models alone.**

Accurate heat loads lead to [properly sized heat pumps](https://hvacknowitall.com/blog/heat-pump-oversizing-what-every-hvac-tech-needs-to-know), which avoid the comfort issues, short cycling, and poor dehumidification that come with oversized equipment.

---

*This article is Part 2 of a 3-part series on heat load calculations and proper HVAC sizing by Drew **Tozer** for HVAC Know It All.* *Read [**Part 1**](https://hvacknowitall.com/blog/heat-load-factors-a-simplified-method-for-10-second-load-calculations) & **[Part 3.](https://hvacknowitall.com/blog/hvac-design-heat-load-factors-shortcut)***

--------------------------------------------------

# ID: 5974

## Title: HVAC Design Heat Load Factors: A Simplified Method for 10-Second Load Calculations

## Type: blog_post

## Author: Drew Towzer

## Publish Date: 2025-07-09T22:16:53

## Word Count: 1040

## Categories: Heat Pumps, HVAC Installation

## Tags: accurate heat loads, duct capacity, energy efficiency, energy modeling, F280, heat load calculation, heat pump sizing, heating requirements, HOT2000, HVAC comfort, HVAC design, HVAC Know It All, HVAC professionals, HVAC sizing, load matching, Manual J, oversized equipment, performance-based calculation, right-sized HVAC, short cycling

## Permalink: https://hvacknowitall.com/blog/hvac-design-heat-load-factors-simplified-method-load-calculations

## Description:

[](https://www.amazon.ca/dp/1781339163/)

*This article is **Part 1** of a 3-part series on heat load calculations and proper HVAC sizing by Drew Tozer for HVAC Know It All. Read **[Part 2](https://hvacknowitall.com/blog/heat-loads-in-the-real-world-precision-versus-accuracy)** & **[Part 3](https://hvacknowitall.com/blog/hvac-design-heat-load-factors-shortcut).** Drew’s book “**[Feel-Good Homes](https://www.amazon.ca/dp/1781339163/)**: How to choose the right heat pump for a comfortable, healthy, sustainable home” is available for purchase now.* *NOTE: This information is tailored towards cold climates / heating-dominated regions.*

## HORSESHOES, HAND GRENADES, AND HEAT LOADS: THE ART OF GETTING CLOSE ENOUGH

Heat pump sizing comes in intervals of 6,000 BTU/hr (half-ton) so *close enough* is the only reasonable goal for heat load calculations. Calculating heat loads down to a single BTU/hr won’t change equipment selection.

Heat loss calculations like Manual J, F280, and HOT2000 (H2K) have a long list of inputs that can be adjusted and manipulated in minute detail. This level of control gives the illusion of accuracy but you’re actually getting its cousin: precision.

> ***NOTE**: H2K is the energy modelling software developed by National Resources Canada and used by energy advisors (the Canadian equivalent of HERS Raters). For simplicity, I’ll refer to H2K, but the concepts and criticisms apply to other modelling software and methodologies like Manual J and F280.*

**Accuracy means getting close to the right answer.** It’s about being *correct*. But precision is about being *exact*, whether it’s correct or not.

### A Real-World Example

Let’s look at an example from 2023. I was helping a homeowner in Toronto (as a third-party consultant, not as an HVAC contractor). It was a hundred-year-old double-brick row house connected to neighbouring houses on both sides. It was leaky because of an issue in the converted attic. An energy advisor assessed the house, completed an energy model, and created a full report with recommendations.

The report included a heating requirement of 83,052 BTU/hr (6.92 tons) and estimated the house would use 3,971 m³ of gas (1,400 therms) per year for heating. Because of the report, the contractor recommended a 7-ton gas furnace.

Such precision.

**Here’s the problem**: over the previous twelve months, the house only used 1,300 m³ (460 therms) of gas for heating—67% less than the modelled amount. I confirmed that the homeowner hadn’t taken any winter vacations that would’ve skewed the data.

I did a performance-based heat load calculation based on actual gas consumption, and the heat load was 26,000 BTU/hr.

One of the best ways to improve the accuracy of models like H2K is to calibrate the results based on real-world performance data like thermostat runtime or energy consumption. H2K has a **very** strong correlation between modelled gas consumption and heat loss (see figure 1).

**Figure 1. Correlation between modelled gas usage and modelled heat loss for 200 houses in Canada, modelled in HOT200 (H2K) from 2022-2023 under the EnerGuide Rating System (ERS).**

For this house, you can use the *actual* gas consumption and prorate the heat load. The house used 33% of the modelled gas consumption, so the heat load is closer to 33% of 83,052 BTU/hr (27,000 BTU/hr).

It’s not perfect, but it’s getting closer—and *close* is the goal.

## WHY ACCURATE HEAT LOADS MATTER

You can’t get right-sized HVAC without an accurate heat load calculation.

Sure, but why do we want right-sized HVAC?

Comfort, mostly.

But it also has serious implications for heat pumps. [Central ducted heat pumps](https://hvacknowitall.com/blog/central-heat-pump-install-considerations) are often constrained by duct capacity because they need to push more air to move the same amount of heat.

The industry tends to overestimate heating loads, so improving accuracy generally leads to smaller equipment, which reduces the risk of high static pressure.

Smaller equipment will perform better within existing infrastructure, it’ll dehumidify better than oversized equipment, it’ll be quieter and require less maintenance than systems with high duct pressure, and it reduces the odds that the outdoor units will need to be 50% bigger (2 fans instead of 1).

### The Comfort Factor

Let’s talk briefly about **comfort**.

**Oversized HVAC is the underlying cause of many comfort problems.** Traditional contractors oversize equipment as a way to reduce risk: *if it’s too big, it’s not too small*. Or so the thinking goes.

We talk about heating loads like they’re a constant, but it’s an ever-changing state. A house needs a different amount of heating or cooling every hour as outdoor conditions change.

The heat load that we calculate using the 99% design temperature is just a tool to size HVAC systems—but it represents a tiny fraction (by definition, 1%) of the year. The rest of the year has heating and cooling needs too.

And when an HVAC system is oversized, it serves the 0.1% at the expense of the 99.9%. During those hours, the system can’t match the needs of the house.

That means short-cycling equipment, which leads to hot and cold rooms on the top floor of the house because the system isn’t running long enough to provide conditioned air to those floors. The thermostat on the main floor tells the furnace to turn off, long before that happens.

Right-sized HVAC is better at **load matching**, so it can provide the right amount of heating or cooling during more hours of the year. The system can *match* the needs of the house.

In most cases, [right-sized HVAC needs to include a heat pump](https://hvacknowitall.com/blog/heat-pump-oversizing-what-every-hvac-tech-needs-to-know) (either fully electric or installed as a hybrid with a furnace for backup heat—the right option depends on the local climate and the specific house). Even the smallest furnace on its lowest setting is too big for an average house.

Check out this podcast where Gary and I demystify how properly sized heat pumps eliminate hot and cold spots in homes, debunking outdated myths while explaining how modern systems deliver superior comfort and efficiency even in cold climates without requiring oversized equipment or always needing gas backup.

---

*This article is Part 1 of a 3-part series on heat load calculations and proper HVAC sizing by Drew **Tozer** for HVAC Know It All. Read **[Part 2](https://hvacknowitall.com/blog/heat-loads-in-the-real-world-precision-versus-accuracy)** & **[Part 3](https://hvacknowitall.com/blog/hvac-design-heat-load-factors-shortcut).***

*For more on heat pump sizing considerations, check out Gary’s article on [Important Considerations for Heat Pumps](https://hvacknowitall.com/blog/central-heat-pump-install-considerations), where he discusses the critical balance between heating load, cooling load, and duct capacity.*

--------------------------------------------------

# ID: 5951

## Title: Heat Pump Reversing Valves Explained: How They Work in HVAC Systems

## Type: blog_post

## Author: Julian Finbow

## Publish Date: 2025-06-17T17:27:05

## Word Count: 1238

## Categories: Heat Pumps, Components

## Tags: bi-directional components, cooling mode, defrost cycle, differential pressure, discharge gas, heat pump, heat pump diagnosis, heat pump maintenance, heating mode, HVAC components, HVAC troubleshooting, O/B terminal, pilot lines, refrigerant flow, refrigeration cycle, residential HVAC, reversing valve, reversing valve failure, seasonal changeover, solenoid coil

## Permalink: https://hvacknowitall.com/blog/heat-pump-reversing-valves-explained-how-they-work-in-hvac-systems

## Description:

## Introduction

**Heat Pumps** have become increasingly prevalent in the HVAC industry, and they’re not going anywhere. I remember learning about the Reverse Refrigeration Cycle, and wanting it to go away until I was more confident with the “Forward Refrigeration Cycle”. With most everyone working with Heat Pumps, being comfortable with their operating premise and their unique component, the **Reversing Valve** is of paramount importance.

If you’re looking to deepen your understanding of heat pump systems, check out our [General Guide to HVAC Troubleshooting](https://hvacknowitall.com/blog/hvac-troubleshooting) where we cover fundamental diagnostic approaches that apply to heat pump systems.

## Heat Pump Terminology

Instead of saying “**[Evaporator](https://hvacknowitall.com/blog/understanding-evaporator-coils-types-function-troubleshooting-tips)**” and “**[Condenser](https://hvacknowitall.com/blog/refrigeration-ac-condensers-the-critical-heat-dissipaters-in-hvac-systems)**“, a Heat Pump’s Coils are referred to as Indoor, and Outdoor. The **Indoor Coil** is made cool in the summer to provide air conditioning, and it is made warm in the winter to provide heating. The **Outdoor Coil** is opposite to this.

This function is obtained simply by redirecting the refrigerant flow to be “opposite” of normal air conditioning, when the unit runs in heating mode. This is possible by the use of a **Reversing Valve**. There are some specialized components, such as **[Bi-Directional Driers](https://hvacknowitall.com/blog/driers-and-sight-glasses),** which allow this to work, but will not be described in this writing for simplicity.

> 🎧 **LISTEN:** Want to hear more about heat pump operation? Check out our [How TX Valves Adapt to Multiple Refrigerants and Improve Heat Pumps podcast with Jamie Kitchen](https://podcasters.spotify.com/pod/show/hvacknowitall/episodes/How-TX-Valves-Adapt-to-Multiple-Refrigerants-and-Improve-Heat-Pumps--Jamie-Kitchen--Part-1-e2ut22g) where Gary explores heat pump components and operation.

>

> https://podcasters.spotify.com/pod/show/hvacknowitall/episodes/How-TX-Valves-Adapt-to-Multiple-Refrigerants-and-Improve-Heat-Pumps–Jamie-Kitchen–Part-1-e2ut22g

## System Layout

The **Basic Refrigeration Cycle** gets some bells and whistles for a Heat Pump with a Reversing Valve.

The left side represents cooling (normal), and the right side represents heating, where the cycle is reversed. The **[Compressor](https://hvacknowitall.com/compressor-issues)** and other components continue to run during a changeover, while the Reversing Valve changes position.

For example, if the system is running in Cooling, and a call for Heating is required, the Reversing Valves’ Solenoid Coil is energized. This causes the Reversing Valve’s Solenoid Valve to change positions, allowing discharge gas to be sent to the indoor coil to heat the space. In the meantime, the Outdoor Coil extracts the **Enthalpy** available from the outdoors.

**Note:** in the heating cycle, a defrost must occur to free the Outdoor Coil of frost. This is done by simply again “Reversing” the system flow so that Discharge Gas temporarily provides its heat to the Outdoor Coil. For proper heat pump installation in cold climates, consider adding a drain pan heater as demonstrated in our [How To Install A Drain Pan Heater On A Cold Weather Heat Pump](https://www.youtube.com/watch?v=atiXmN2swgA) video.

## How the Reversing Valve Works

The Reversing Valve utilizes differential pressure to get the “Valve” to move. This is achieved through utilizing High Pressure Discharge gas to flow through the valve’s “**Pilot Lines**“, to influence the movement of the Valve.

On the left side of the above image, Discharge gas is shown routing through the Pilot Line to push the Reversing Valves’ cylinder towards the left. This orientation allows for Discharge Gas (red) and Suction Gas (blue) through the Valve in the shown path. This state could realize the Solenoid Coil being deenergized.

On the right side of the above image, think of the Solenoid Coil being energized. This causes the Solenoid Valve to change positions, and provide a new Discharge Gas Path within the Pilot Lines. The new path pushes the cylinder towards the right side of the Reversing Valve. This allows the second orientation of Discharge and Suction Gas through the valve.

In cooling, the Discharge gas goes through the Reversing Valve, and to the Condenser. When the solenoid is energized, the reversing valve pushes Discharge Gas to the indoor coil for heating.

## Control Designation and Regional Considerations

Different manufacturers use different control strategies for their reversing valves. As explained in our article on [Heat Pump Reversing Valves and Their Control Designation](https://hvacknowitall.com/blog/reversing-valves-and-their-control-designation), most manufacturers default to heat (O terminal is energized for cooling), though some still default to cooling (B terminal is energized for heating).

**Note:** Different areas (Toronto vs. Miami) have different failure modes for the Heat Pump/Reversing Valve. In a market with cold winters such as Toronto, the unit will fail to Heating. In a warmer market (Miami), the unit will fail to provide Cooling. The common failure is the Solenoid Coil burning out, so failure occurs with the Solenoid Coil deenergized.

Some manufacturers that use B terminal designation (energize for heating) include:

- Rheem

- Ruud

- Weathermaker

- Ameristar

- Bosch Air Source

Always consult the manufacturer’s documentation for specific wiring information, as incorrect terminal connections can cause the system to operate in the opposite mode than intended.

## Common Reversing Valve Issues and Troubleshooting

For practical troubleshooting guidance, you can also check out our [Quick Heat Pump Troubleshooting and Diagnosis](https://www.youtube.com/watch?v=nQ3toZhtMZM) video that demonstrates common issues.

### Valve Stuck in One Position

- **Symptoms:** System runs in only heating or only cooling mode regardless of thermostat setting

- **Diagnosis:**

- Verify proper voltage to the solenoid coil (typically 24V)

- Check temperature difference across the valve in both modes

- Listen for the distinctive “click” when the valve should change over

- **Solution:**

- If solenoid receives proper voltage but doesn’t activate, replace the coil

- If solenoid activates but valve doesn’t shift, valve may need replacement

- In some cases, rapidly cycling between heating and cooling can free a stuck valve

### Leaking or Bypassing Valve

- **Symptoms:** Poor performance in one or both modes, inability to maintain temperature

- **Diagnosis:**

- Listen for hissing sounds indicating internal leakage

- Check for abnormal temperature readings across valve ports

- Monitor system pressures for irregularities

- **Solution:**

- Replacement is typically required as internal repair is not practical in the field

### Solenoid Coil Failure

- **Symptoms:** System operates in default mode only

- **Diagnosis:**

- Test coil resistance (typically 50-80 ohms for 24V coils)

- Check for voltage at the coil terminals when mode change is called for

- Inspect for physical damage or burn marks on the coil

- **Solution:**

- Replace the solenoid coil if failed

- Check control wiring and thermostat settings after replacement

> 🎧 **LISTEN:** For more on heat pump component troubleshooting, listen to our [Refrigeration Side Troubleshooting podcast with Jamie Kitchen](https://podcasters.spotify.com/pod/show/hvacknowitall/episodes/Refrigeration-Side-Troubleshooting-wJamie-Kitchen-e2d9u0q) where they discuss refrigeration system diagnostics.

>

> https://podcasters.spotify.com/pod/show/hvacknowitall/episodes/Refrigeration-Side-Troubleshooting-wJamie-Kitchen-e2d9u0q

## Summary

Heat Pumps are everywhere, and understanding their operating principle is very important. Reversing Valves are an integral part of a Heat Pump, and they are important to understand. Many Heat Pump operational, troubleshooting, and repair scenarios relate directly to it.

The Reverse Refrigeration Cycle is demystified when its operation and the Reversing Valves’ function are understood. Being comfortable with the operating principle of the Reversing Valve allows a technician to be successful when diagnosing issues with Heat Pump Systems.

To learn more about related components in heat pump systems, check out the discussion on expansion devices in our podcast episode with Jamie Kitchen on [How Europe is Beating North America in HVAC Innovation](https://podcasters.spotify.com/pod/show/hvacknowitall/episodes/How-Europe-is-Beating-North-America-in-HVAC-Innovation--Jamie-Kitchen--Part-2-e2v4e48).

https://podcasters.spotify.com/pod/show/hvacknowitall/episodes/How-Europe-is-Beating-North-America-in-HVAC-Innovation–Jamie-Kitchen–Part-2-e2v4e48

> 📺 **WATCH:** For a visual demonstration of heat pump operation in different building applications, watch our [Water Cooled Heat Pumps, Air Conditioners and Coaxial Coils video](https://www.youtube.com/watch?v=LHJjDfZXUOM) where Gary explains heat pump components in building loops.

--------------------------------------------------

# ID: 5941

## Title: BMS User Interfaces: From Graphics to Mobile Dashboards

## Type: blog_post

## Author: Ben Reed

## Publish Date: 2025-06-05T13:48:46

## Word Count: 1395

## Categories: Automation

## Tags: alarm management, BMS interface, BMS navigation, BMS workstation, building automation dashboards, building automation software, building controls visualization, graphical user interface, HVAC dashboard shortcuts, HVAC graphics, HVAC user interfaces, mobile BMS apps, trend analysis

## Permalink: https://hvacknowitall.com/blog/bms-user-interfaces-dashboards

## Description:

Picture this: You’re called to troubleshoot a hot complaint on the fifteenth floor. You arrive at the mechanical room, sit down at the BMS workstation, and… freeze. The screen is filled with animated graphics, flashing icons, and enough data to make your head spin. Where do you even click first? How do you find the VAV box serving that space? And why does this interface look like it was designed by someone who’s never actually fixed an HVAC system?

If you’ve ever felt overwhelmed by a BMS interface, you’re not alone. Many technicians receive extensive training on mechanical systems but minimal instruction on navigating the digital dashboards that control them. Yet in today’s world, your ability to efficiently use these interfaces directly impacts how quickly you can diagnose problems and keep tenants comfortable.

Let’s demystify BMS interfaces—from their humble beginnings to today’s mobile apps—and give you the confidence to navigate any system you encounter.

## From Green Screens to Glass Screens: The Evolution of BMS Interfaces

Understanding where BMS interfaces came from helps explain why they work the way they do today. Each generation built upon the last, carrying forward both improvements and legacy quirks.

### The Command Line Era (1980s)

Early BMS interfaces were text-based, requiring operators to type commands like:

```

DISPLAY AHU1.SAT

SET AHU1.STPT = 55

TREND AHU1.SAT INTERVAL=5MIN DURATION=24HR

```

These systems were powerful but required memorizing commands and syntax. Technicians needed to know exact point names and command structures to get anything done. The learning curve was steep, but once mastered, experienced operators could work quickly.

### The Graphic Revolution (1990s-2000s)

As computing power increased, graphical interfaces became the norm. System integrators created animated schematics of equipment with live data overlays. Suddenly, operators could see a visual representation of the systems they managed.

This era introduced the familiar elements we still see today:

- Equipment graphics showing real-time status

- Color-coding to indicate alarms and state changes

- Navigation trees to browse building systems

- Point-and-click access to commands and setpoints

While more intuitive than command lines, these interfaces often suffered from clutter, inconsistent design, and hardware limitations. Many were custom-built for each installation, meaning no two systems looked quite the same.

### The Web-Based Transition (2000s-2010s)

As internet technologies matured, BMS interfaces moved to web browsers. This brought several advantages:

- Access from any computer on the network

- No specialized software installation required

- Easier updates and maintenance

- More standardized user experience

However, early web interfaces were often slow and limited by browser capabilities of the time. Security concerns also emerged as systems became accessible remotely.

### The Mobile Revolution (2010s-Present)

Today’s BMS interfaces extend beyond desktop computers to tablets and smartphones. Modern systems offer:

- Responsive designs that adapt to any screen size

- Touch-optimized controls for field use

- Location awareness that shows nearby equipment

- Push notifications for critical alarms

- Cloud-based access from anywhere

For examples of how different BMS systems handle core control functions, check out our article on [BMS Control Fundamentals](https://hvacknowitall.com/blog/bms-control-fundamentals).

## Critical Interface Elements: What to Look For

Despite variations between manufacturers, all modern BMS interfaces share common elements. Understanding these components helps you navigate unfamiliar systems quickly.

### System Navigation

The navigation structure is your map through the building’s systems. Typically organized as a hierarchical tree, it might be arranged by:

- Building → Floor → Zone → Equipment

- System Type → Equipment → Components

- Mechanical Systems → Electrical Systems → Security

The navigation panel is usually on the left side of the screen. Look for expand/collapse icons (+ or -) to reveal deeper levels.

### Equipment Graphics

These visual representations show the status of mechanical systems. Look for:

- Animated components (spinning fans, opening valves)

- Color-coded status indicators (green = normal, red = alarm)

- Real-time data values overlaid on equipment

- Interactive elements you can click for more detail

In most systems, right-clicking on components reveals additional options like commanding, trending, or viewing properties.

### Alarm Management

Alarm displays show current and historical issues requiring attention. Key features include:

- Severity indicators (critical, warning, notification)

- Acknowledgment status (new, acknowledged, returned to normal)

- Filtering options to focus on specific systems or alarm types

- Detailed descriptions and recommended actions

Effective alarm management is crucial—when everything becomes an “alarm,” technicians develop alarm fatigue and start ignoring notifications.

### Trend Analysis

Trend graphs display how values change over time, essential for diagnosing intermittent issues and identifying patterns. Look for:

- Multi-variable graphing capabilities

- Flexible time range selection

- Export options for further analysis

- Comparison features for similar equipment

To understand how these interfaces connect to the underlying network infrastructure, see our article on [BMS Network Architecture](https://hvacknowitall.com/blog/bms-network-architecture-communication).

## Interface Efficiency Tips for HVAC Technicians

The difference between a BMS novice and expert isn’t just knowledge—it’s efficiency. Here’s how to navigate interfaces like a pro:

### 1. Master the Search Function

Most modern BMS interfaces include powerful search capabilities. Instead of clicking through nested menus, search for specific:

- Room numbers or names

- Equipment tags

- Point types (temperature, pressure, etc.)

- Alarm conditions

Example: Rather than navigating through Building → Floor 3 → East Wing → VAV-3-12, simply search for “VAV-3-12” or “Room 315 temp.”

### 2. Learn Keyboard Shortcuts

Power users rely on keyboard shortcuts to work quickly:

- F5 to refresh data

- Ctrl+F to find text on the current page

- Tab to move between fields

- Esc to cancel operations or close dialogs

Each system has its own shortcuts—look for a “Help” section that lists them.

### 3. Use Multi-Window Techniques

Open multiple windows or tabs to compare different systems simultaneously:

- View the AHU and its VAV boxes side-by-side

- Compare similar equipment performance

- Keep alarm lists visible while troubleshooting

Most web-based systems support this natively; older applications might require specific “new window” commands.

### 4. Create Personalized Views

Many systems allow customized dashboards showing your most-used information:

- Group frequently accessed equipment

- Configure multi-trend graphs for key parameters

- Save custom filter settings for alarms

- Create shortcut links to common tasks

Spending time setting up these dashboards pays dividends in daily efficiency.

### 5. Leverage Mobile Features

When using tablet or smartphone interfaces:

- Use QR codes or NFC tags to quickly access equipment pages

- Take advantage of location-based filtering

- Configure notifications for critical systems

- Save offline documentation for areas with poor connectivity

## Mastering Any Interface

Regardless of the specific BMS you encounter, these strategies will help you quickly become proficient:

1. **Start with Navigation**: Spend 10 minutes exploring the menu structure. Where are alarms? Trends? Graphics? Schedules?

2. **Find the Search**: Almost every modern BMS has search functionality. It’s often faster than clicking through menus.

3. **Learn the Nomenclature**: Every building has a point naming convention. Decode it early. (AHU1.SAT = Air Handler 1, Supply Air Temperature)

4. **Master Right-Click**: Many functions hide in right-click context menus. Try right-clicking on graphics, point names, and values.

5. **Use Help Functions**: Most systems have built-in help. F1 is your friend when stuck.

6. **Take Screenshots**: Document complex navigation paths or useful screens for future reference.

7. **Ask Questions**: Building operators often know shortcuts and tricks not found in manuals.

## Your Interface Journey

BMS interfaces have evolved from cryptic command lines to intuitive mobile apps, yet each generation builds upon the last. Understanding this evolution helps you adapt to any system—whether it’s a 30-year-old text-based interface or cutting-edge AI-powered dashboard.

Remember, the interface is just a window into the mechanical systems you already understand. The same troubleshooting logic applies whether you’re reading a gauge on a pipe or a value on a screen. The difference is that modern interfaces provide more data, more quickly, from more locations than ever before.

As interfaces continue evolving, stay curious. Each new feature—from mobile access to voice control—is designed to help you work more efficiently. Embrace these tools while maintaining your fundamental HVAC knowledge, and you’ll thrive in an increasingly digital trade.

The next time you sit down at an unfamiliar BMS workstation, take a breath. You understand HVAC systems. You understand troubleshooting. The interface is just another tool in your toolkit—one that becomes more powerful as you master its capabilities.

For a comprehensive introduction to building automation systems, check out our [BMS Basics](https://hvacknowitall.com/blog/bms-basics-hvac-technician-guide) article.

--------------------------------------------------

# ID: 5940

## Title: BMS Network Architecture: How Complex HVAC Control Systems Communicate

## Type: blog_post

## Author: Ben Reed

## Publish Date: 2025-06-05T13:36:17

## Word Count: 1298

## Categories: Automation